Part 2:The basic spray patterns

There are 4 basic spray patterns that water can be “flung” in.

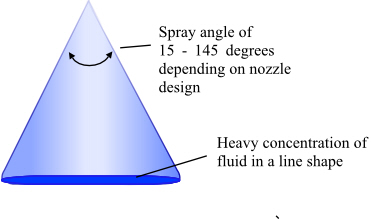

Flat fan

Flat fan

The liquid is shaped into a fan shaped sheet of fluid. This can be comprised of droplets or a more or less coherent sheet of water like a waterfall. Flat fans can have a spray angle of between 15 and 145 degrees depending on the nozzle design.

Fans can be formed by a simple shaped orifice or by deflecting a spray on a shaped deflection surface.

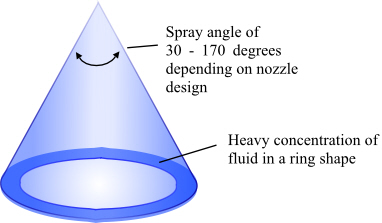

Hollow cone

The liquid is broken into droplets that are heavily concentrated at the edges of the cone of spray produced. This cone can vary from 30 to 170 degrees in spray angle depending on the nozzle design.

The liquid is broken into droplets that are heavily concentrated at the edges of the cone of spray produced. This cone can vary from 30 to 170 degrees in spray angle depending on the nozzle design.

Hollow cone patterns can be formed by three basic designs of nozzle

- The axial whirl design of nozzles where internal veins cause the fluid to swirl and prior to exiting from the orifice

- Tangential whirl nozzles where the fluid is set in to a whirl pool motion by having the exit orifice offset from the centre and perpendicular to the feed pipe.

- Spiral design nozzle (where the fluid is impacted on a protruding spiral shape breaking it apart).

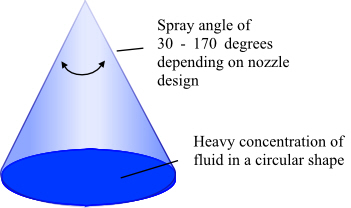

Full cone

In a full cone nozzle the liquid is broken into droplets that are more or less evenly concentrated in the cone of spray produced. Again this cone can vary form 30 to 170 degrees depending on nozzle design.

Full cones can be formed by axial and tangential whirl nozzles as well as spirals.

Solid stream

A simple jet of focused fluid that has no true droplets. A solid stream will be formed by forcing the fluid through a shaped orifice that focuses the spray into a jet.

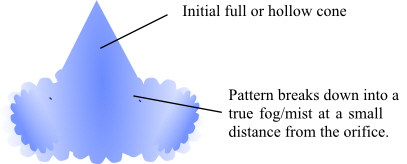

One further pattern, which is not a true pattern per se, should be also be included in any discussion of sprays.

Misting / fog

This is a homogeneous fog or mist with little or no impact. The pattern will start out as a full or hollow cone but at a very short distance from the nozzle orifice the pattern will loose coherence and form a fog or mist.

This is a homogeneous fog or mist with little or no impact. The pattern will start out as a full or hollow cone but at a very short distance from the nozzle orifice the pattern will loose coherence and form a fog or mist.

Many hollow and full cone nozzles will eventually form a mist if sprayed at sufficient pressures. But there are two designs of nozzle that seek to achieve misting deliberately.

- The small orifice nozzle will operate at high pressures pushing fluid through a very small opening to break it apart into a fog.

-The impingement nozzle will impact a stream of fluid onto a pin directly below the orifice. This literally smashes the fluid apart into a fog.

The 5 critical characteristics of a spray

The basic spray pattern types above, with the exception of misting, allow for simple trigonometry to calculate the area being sprayed. This, along with data on the flow rates at given pressures, constitutes the starting point of spraying system design. These basic coverage and dosing details though say very little about the consistency and nature of the spray. Below we examine the 5 critical characteristics of a spray, why they are important and what factors affect them.